Blocked Bit When Drilling With Mud

Have you ever blocked your bit off when drilling with mud and when you pull out you find that the bit and the first one or two drill rods above the bit are full of sand?

If you are unsure as to the reason why this has happened it is because of an imbalance of mud weight between the borehole annulus and the inside of the drill rod and the principal causes are:

- Insufficient circulating time before making a new connection

- Drilling without a Non Return Valve

A sign that your mud is not balanced out is when you stop pumping and un-screw the rotary head to make a connection and mud starts jetting out of the tool joint in the table. This has been come across on many occasions where the driller thinks he has artesian pressure or is beginning to experience some kind of blow out. When really all that is happening is that the mud that is carrying all the cuttings up the annulus is heavier than the mud that is inside the drill rods, so when the pump stops the two weights of mud want to balance out and the heavier mud plus cuttings start to flow up through the bit and up the drill rods. If the difference in pressure is significant and you leave it to flow the column of mud laden with cutting will be perhaps 6m to 12m up inside the drill rods above the bit. Then when you make a new connection and start the pump again the cuttings inside the drill rods begin to pack off the bore as they cannot escape fast enough. The pressure builds up on your mud pump until you are blocked off. The more you try to blow the cuttings out the more compact they become in the bore of the drill rods above the bit.

To avoid these set of circumstances you should consider the following:

Insufficient Circulating Time Before Making a New Connection

When carrying out any form of drilling it is critical that you know how fast the cutting are travelling up the annulus or as it is properly described, knowing your “Up Hole Velocity” (UHV).

We are always drilling with mud pumps that are too small for the diameter that we want to drill. For example a very common size of mud pump used is the 5” x 6”, which has a 5” diameter piston and a 6” stroke. This pump will deliver 580 litres per minute at maximum rpm. So for practical purposes you are looking at about 80% of this figure which will be around 464 litres per minute.

If we are drilling a 12-1/4” hole with 3-1/2” drill rods and the pump is producing 464 litres per minute then the UHV of the fluid rising up the annulus will be 20ft per minute or 6 metres per minute.

So if you are at 50m and want make a connection, you should circulate for at least 8minutes before stopping the pump and making a new connection (50 ÷ 6 = 8 minutes).

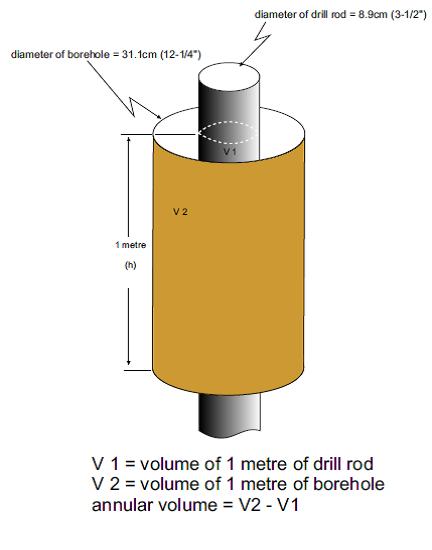

To calculate your annular volume per meter you need to deduct the volume of the drill rods from the volume of the hole. See figure 1 below:

Figure 1

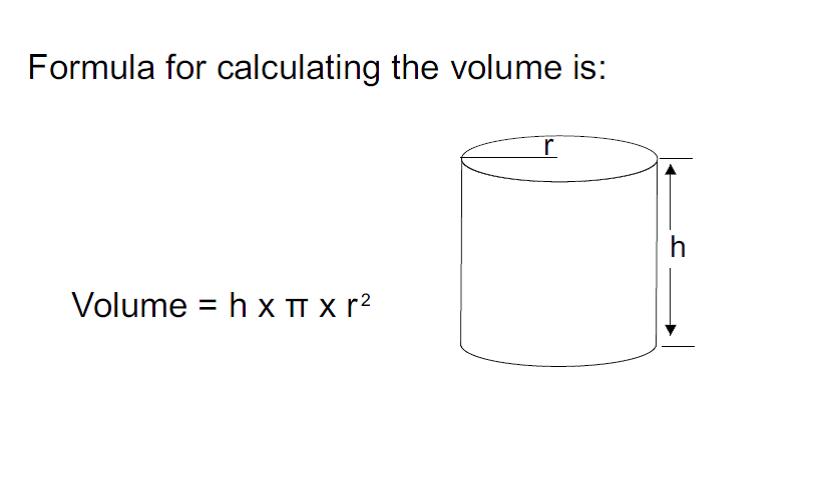

To calculate the cylindrical volumes in litres use the formula in Figure 2 stating figures in centimetres:

Figure 2

To follow our example:

Bore hole volume V2 = 100 x 3.14 x 15.552 So V2 = 75.92 or 76litres.

Drill rod volume V1 = 100 x 3.14 x 4.452 So V1 = 6.21 litres.

76 – 6.21 = 69.79 litres or to round up we will say 70 litres per meter this is your ANNULAR volume per meter.

If the mud pump is delivering 464 litres per minute and we know that our annular has 70 litres per meter then we can calculate the speed or velocity that the mud is travelling up the hole.

464 ÷ 70 = 6.62. This means that our mud is travelling 6.6 meters in one minute. If the hole is 50 meters deep then this is 50 ÷ 6.6 = 7.5 minutes or “8 minutes”.

So now you have an idea of the speed at which the mud is travelling up the hole.

If you are unsure of what capacity your mud pump is giving then measure the flow coming out of the bore hole by timing how long it takes to fill a container with a known volume in litres.

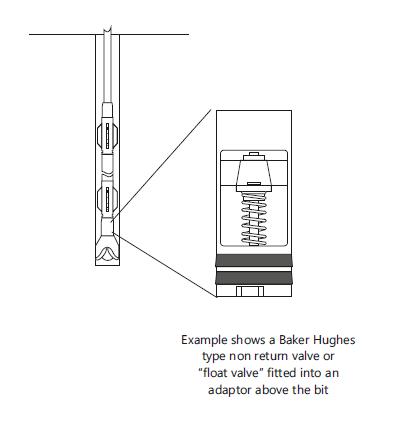

Drilling Without a Non Return Valve (NRV)

When drilling conventional mud it is always good practice to run an NRV just above the bit, this will help avoid back pressure from the annulus entering the bore of the drill rods and will prevent the accumulation of long columns of sand getting trapped behind the bit. (See Figure 3)

Figure 3

Using the NRV does not mean you should not worry about knowing what your UHV is, the NRV is a physical control over the imbalance of mud but you should always make sure you are cleaning your hole properly and this means:

- Knowing your UHV

- Circulating for the correct amount of time to ensure that the cuttings at the bottom of the hole are removed to the surface.

- Good mud cleaning.