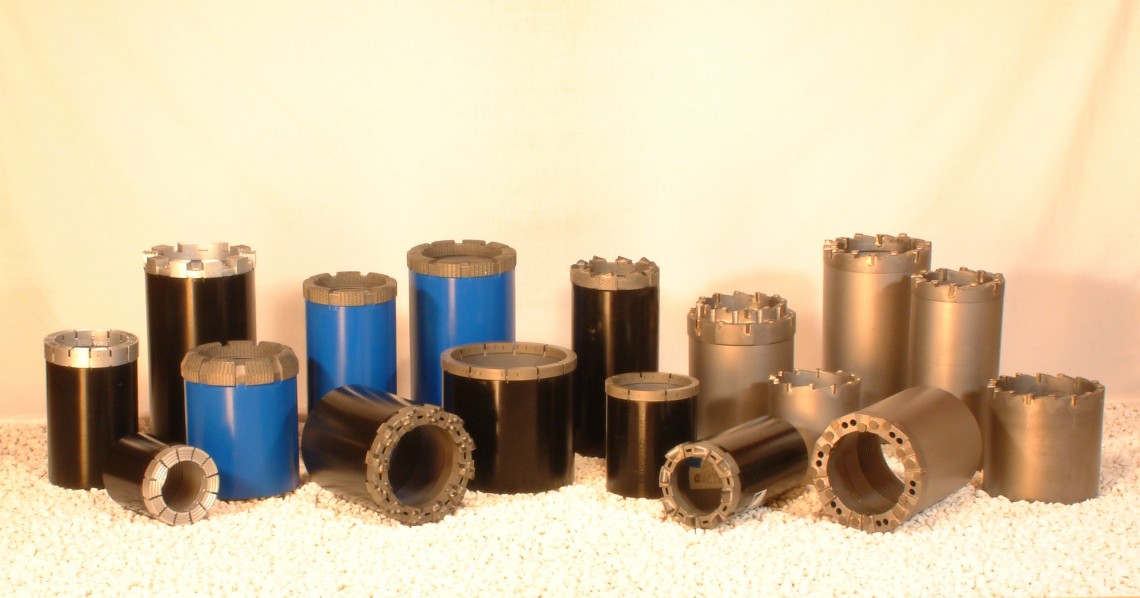

Core Bits

Dando’s ‘Destroyer’ range of core bits are used globally by clients in both the mineral and geotechnical sectors, receiving positive feedback for their high performance rates and longevity.

All bits are manufactured to conform to accepted drilling industry standards but can also be supplied in non-standard designs for clients with specific requirements.

There are four types of cutting media to accommodate the various types of geology:

Impregnated diamond type for hard rock formations

Impregnated core bits are manufactured by bonding diamonds into a matrix which wears away during drilling to continually expose the diamonds for the cutting of rock. This process has distinct advantages over surface set bits, which can shed diamonds from the matrix leading to premature bit failure, due to the bit drilling out the diamonds.

The disadvantage of impregnated bits is that if the wrong matrix is selected or the bit is allowed to ‘run on bottom’ without penetrating the matrix can ‘polish’ preventing further diamonds from being exposed. The bit then has to be ‘mechanically’ stripped to expose further diamonds. Therefore matrix selection for impregnated bits is an important factor and often is a matter of initial trial and error.

Generally the harder the rock, the softer the matrix. A numerical identification system for has been established for these bits:- I =The hardest matrix up to 15 = The softest matrix.

Surface set diamond type for medium-hard conditions

Surface set bits are manufactured for high speed penetration, long service life and suitability for a variety of rock conditions. The range includes a variety of face profiles, diamond grades and stone sizes, enabling our customers to choose a bit that will provide optimum performance in any formation.

Polycrystalline diamond type for soft-medium conditions (TSP & PCD).

The PCD bits have the same profile as sawtooth design bits, but the cutters are composed of Polycrystalline Diamond (PCD) which give a long working life, fast penetration and a high percentage core recovery in soft and hard formations, from clay to hard limestones. These bits are suitable for use with air, water, mud or foam flush. Several types of PCD cutters are available depending on the formation to be cored such as flat, clam or claw.

Tungsten carbide type for very soft conditions.

Tungsten carbide core bits are available to suit most sizes of core barrel, and come in a variety of types to suit different drilling conditions. Sawtooth design of bits can have various types of inserts:

Rectangular

Most commonly used type in sawtooth crown bits. Available as face discharge or internal

discharge depending on the application.

Taper

Where a larger surface area of cutting area is needed to achieve greater rates of penetration,

taper insert core bits are used. This gives an efficient clearance of cuttings due to the profile of the

bit. This type of bit is normally used in soft formations.

Octagonal

This is the type of insert associated with thin wall core barrels such as the T2 and T6 metric series.

It has the advantage of a large number of cutting surfaces giving optimum penetration rates.

Fragmentary

Fragmentary inserts are useful in highly fractured formations or those containing loose pebbles.

The cutting surface is over the whole of the bit and so the wear on the bit is evened out, and new

tungsten carbide is exposed throughout the drilling process. This type of bit is less susceptible to

chipping or impact damage.