Jackal 9000 Multipurpose Drilling Rig

The Dando Jackal 9000 is a truly multipurpose drilling rig incorporating a pullback capacity of 10,000kg within a lightweight and compact structure.

Designed for use in water well, mineral exploration, geotechnical investigation and geothermal (GSHP) drilling projects, the Jackal 9000 is capable of performing various drilling techniques including RC (Reverse Circulation), RAB (Rotary Air Blast), conventional mud, auger, diamond wireline coring, SPT, geothermal heat pump drilling and more.

*Please request a copy of our terms and conditions if required.

| CARRIER | |

|---|---|

| Standard | Track mounted - various track options available. Umbilical tracking |

| Other Options | Heavy duty commercial 4 x 4 truck |

| Trailer | |

| Skid | |

| Mounted on customer own support vehicle/structure | |

| DECK ENGINE | |

| Type | Caterpillar C4.4 (140hp) or C7.1 (225hp) diesel engine |

| Other options available | |

| MAST CAPACITY | |

| Pullback | 10000 kg |

| PullDown | 3250 kg |

| Hookload (Max) | 10000 kg |

| Working Stroke (Main Winch) | 5500 mm |

| Working Stroke (Rotary Head) | 3700 mm |

| Mast Dump | 45 degrees |

| HEAD TRAVERSE | |

| Hoist | 6m/m (20ft/min) |

| Rapid Hoist | 26m/min (85.5ft/min) |

| Feed | 20.25m/min (66ft/min) |

| Rapid Feed | 36.5m/min (120ft/min) |

| ROTARY HEAD | |

| Rotary Head Performance (Standard) | Rotation (max): 436 rpm |

| Torque (max): 6000 Nm | |

| Rotary Head Performance (Option 1) | Rotation (max): 750 rpm |

| Torque (max): 4000 Nm | |

| Other options available | |

| Features | Rotary head tilt and side shift |

| DRILL TABLE & BREAKOUT SYSTEM | |

| Type | Double acting hydraulic make up and breakout clamp. |

| Clamping Diameter | 60mm (min) - 250mm (max) |

| Other options available | |

| HYDRAULIC SYSTEM | |

| Type | Hydraulic power circuit based on load sensing hydraulic pumps and proportional control valves with auxilery quick connect circuit |

| MAIN WINCH | |

| Single Line Pull (Max) | 3200kgf |

| Single Line Speed (Max) | 41 m/minute |

| Drum Capacity (13mm wirerope) | 65 m |

| WIRELINE WINCH (OPTIONAL) | |

| Single Line Pull (Max) | 1000 kg |

| Single Line Speed (Max) | 120 m/minute |

| Drum Capacity (4.76 mm wirerope) | 1150 m |

| Other options available | |

| CORING PUMP | |

| Type | FMC hydraulically driven duplex pump |

| Flow Rate (Max) | 146 litres/minute |

| Discharge Pressure (Max) | 700 psi |

| Other options available | |

| INLINE OIL LUBRICATOR | |

| Type | Fitted as standard and used when operating a DTH hammer |

| CONTROL PANEL | |

| Type | Uncomplicated and user friendly with ergonomic layout mounted on a swing out arm |

| LEVELLING JACKS | |

| Type | Two front and two rear jacks with individual locking valves |

| LIGHTING & ELECTRICAL SYSTEM | |

| Lighting | Control panel lighting |

| Mast lighting (optional) | |

| Electrical System | 12 V |

| OTHER | |

| Rod Spin Safety Guard | Fitted as standard with speed reduction |

- Small drilling footprint- length=5000mm; Width=1420mm (travelling) 2200mm (working)

- Track mounted as standard, but also available on 4×4 truck, trailer, skid or customer’s own support vehicle.

- Mast dump to 45 degrees

- Arm mounted drilling control

- On board flush pump

- Hydraulic winch

- High-torque, high-speed rotary head with hydraulic side shift and tilt

- Hydraulic rod clamps/breaker

- Safe hands-free rod handler eliminates the need of physical lifting and manipulation of drill rods

- A hydraulically deployed detachable mast section can be fitted for the pulling of 6 metre drill rods.

- Remote umbilical controls for safe and easy tracking of the machine across all terrain

- Hydraulic SPT Device (Optional)

| 4" RC (25kg/m) drill rod | 320m (1050ft) |

|---|---|

| 3-1/2" (13.5kg/m) drill rod | 593m (1946ft) |

| HWL (11.6kg/m) drill rod | 690m (2264ft) |

| NWL (8kg/m) drill rod | 1000m (3281ft) |

* Depths stated are theoretical and based on 80% capacity of the machine. Depths achieved will depend on variables including ground conditions and capability of crew operating the machine.

- RC Drilling Conversion Kit – For reverse circulation drilling applications

- Heavy Duty Winch – Hoisting capacity 6000kg single line pull

- Drill Rod Rack – Mounted on carrier if truck or trailer

- Duplex 5″ x 6″ Mud Pump – When the rig is mounted on a truck or trailer

- Hydraulic Foot Clamp – Jaws to suit B up to P wireline drill rods. Break out system is a double acting hydraulic cylinder with adjustable wrench

- SPT swing in hammer attachment – This drop weight runs on two guide bars guaranteeing a friction free fall. The weight is fully guarded and can be quickly changed for either SPT Testing or Dynamic Probing standards.

- Trip Hammer Speed:- 0 – 45 blows per minute

- Trip Hammer Drop:- 500mm / 750mm

- Trip Hammer Weight:- 50kg / 63.5kg

- Mast extension – A hydraulically deployed detachable mast section that can be fitted to allow the pulling of 6m drill rods.

- Automatic Rod Handler – For increased safety when loading drill rods.

- Track options:

- Option 1= Triple grouser

- Option 2= Single grouser

- Option 3= Rubber plate

Other options available on request

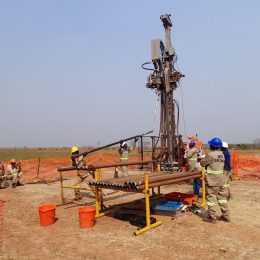

Sudan - Reverse Circulation and Wireline Coring

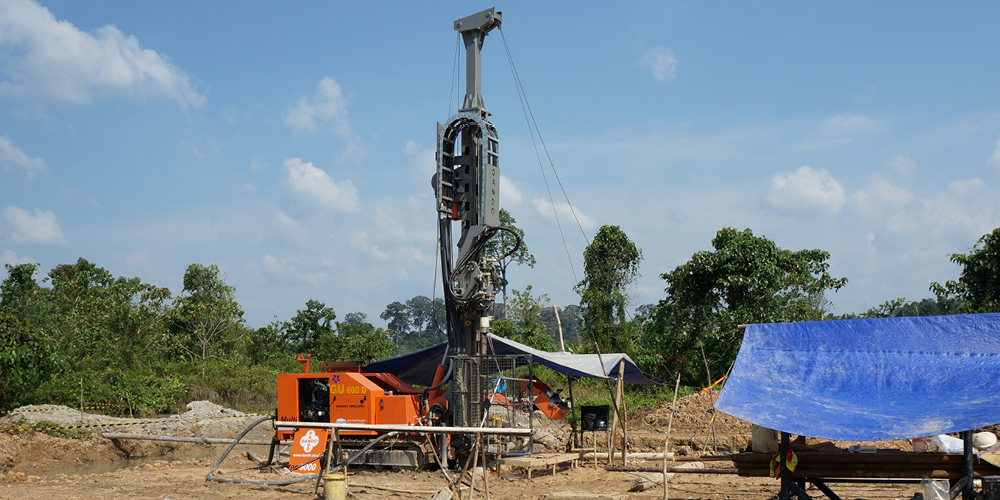

Indonesia - Nickel Exploration - Wireline Coring

One of two Jackal 9000 rigs (Formerly the Multitec 9000) being used for nickel exploration in Sulawesi, Indonesia. The track mounted multipurpose rigs have been conducting wireline coring up to 130m in areas of difficult terrain.

Sudan - Gold Prospecting- Reverse Circulation

4” Reverse Circulation boreholes between 100m and 150m, drilled at angles between 60 degrees and vertical. The rig is also conducting H wireline core drilling to provide further information in select areas.

DRC - Copper Exploration

A mining project independently ranked as the world’s largest discovery of undeveloped, high-grade copper. Featuring the CH400 high speed rotary head and truck mounted for increased mobility, the Jackal 9000 (formerly the Multitec 9000) drilled 10 degrees from vertical with a PWL wireline system to 60m before continuing to 250m with HWL equipment.